Home >

Corporate News >

GIS Intelligent O&M System: Enabling Smarter and More Efficient Mining Operations

Home >

Corporate News >

GIS Intelligent O&M System: Enabling Smarter and More Efficient Mining Operations

2025.12.01

2025.12.01

As industrialization and digitalization continue to deepen, intelligent transformation has become an inevitable trend in the mining sector. Jiangxi Gold Intelligent Service Engineering Co., Ltd. (hereinafter referred to as “GIS”), a wholly owned subsidiary of Nanchang Mineral Systems Co., Ltd. (NMS), leverages the Group’s profound technical expertise and extensive industry experience to deliver comprehensive intelligent operation and maintenance solutions for global mining operations. GIS is committed to creating measurable and sustainable value for its clients.

Traditional mining operations have long faced challenges such as rough equipment management, frequent unplanned downtime, and high O&M costs. Conventional maintenance models can no longer meet the requirements of modern mining. In 2021, NMS partnered with a renowned U.S. automation company to launch the development of an intelligent O&M system and simultaneously established GIS. The company focuses on intelligent O&M, equipment maintenance, technical consulting, process optimization, and spare parts services. Through years of technological development and scenario-based validation, GIS has successfully integrated cutting-edge technologies—such as Industrial IoT and digital twins—with real mining operations, resulting in a mature and reliable intelligent O&M system.

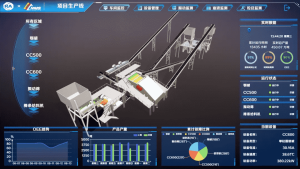

Built on the concept of “one mine, one solution,” the system applies digital twin technologies to enable production line visualization, refined equipment management, and multimodal predictive maintenance. This empowers mines to shift from “reactive repair” to “proactive prevention,” reducing maintenance costs, improving production efficiency, and laying a solid foundation for smart operation.

The intelligent O&M system is structured around three core modules.

The 3D SCADA visualization platform provides a highly realistic digital reproduction of production line operations, integrating critical equipment data to deliver full-process perception and intelligent analysis. The predictive maintenance module utilizes real-time monitoring of vibration, oil quality, product size distribution and other parameters to establish a collaborative control mechanism, achieving both failure prediction and maintenance cost optimization.The AR-based interaction module addresses training challenges through AR-assisted disassembly training and smart inspection glasses, significantly improving onsite operations and remote collaboration efficiency.

The system has been successfully deployed in multiple projects and widely recognized by several major central SOEs. From single-machine intelligence—such as the JC2200 jaw crusher in Henan and the HP300 cone crusher in Jilin—to full-line intelligent upgrades in polymetallic and aggregate projects in Hunan and Fujian, GIS continues to demonstrate the practical value of its solutions. Notably, the system is now operating stably at a major central SOE iron mine in Liaoning, while installation is underway at another large-scale central SOE iron mine in Sichuan. These landmark deployments further highlight GIS’s technical leadership in mining intelligence.

In the Hunan polymetallic project, the system achieved remarkable results through the construction of an equipment health evaluation model: unplanned downtime decreased by 24.7%, equipment failure rate dropped by 35%, and the average monthly maintenance cost per unit fell from RMB 8,530 to RMB 6,620—a reduction of 22.3%. Personnel-related costs were reduced by approximately 15%.

Furthermore, by applying online oil monitoring and optimizing the positive pressure dustproof system, the service life of lubricating oil increased by 50%, significantly reducing lubrication costs. The digital twin–based optimization of startup sequences and load distribution contributed to a 10% reduction in energy consumption, greatly enhancing overall economic efficiency and refined production management.

Looking ahead, GIS will continue to advance technological innovation by deepening the integration of the 3D SCADA system with digital twin models. Real-time data will be used to drive continuous model optimization, enabling precise prediction and intelligent control and regulation of production line conditions. The company will further expand application scenarios, enhance AI algorithm development, and build a full-process intelligent O&M ecosystem.

Intelligent operation and maintenance represent more than a technological upgrade—they signify a reinvention of management philosophy and operational models. GIS looks forward to working with more industry partners to advance global mining toward a safer, more efficient, and more sustainable intelligent future.