2022.08.17

2022.08.17

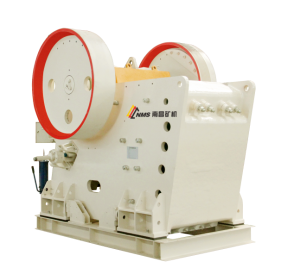

In order to meet the market demand for large-scale equipment, NMS developed JC1200 jaw crusher in 2011, which is applied to the crushing of all kinds of high hardness and high abrasive ores.

In order to further improve the production capacity of the equipment, combined with its actual use, NMS R&D engineer has optimized the eccentricity of main shaft and the size of flywheel, which can better meet customer’s requirements.

Features:

◆Symmetrical crushing chamber design

JC1200 jaw crusher adopts deep symmetrical crushing chamber design to maximize its feeding size, capacity and reduction ratio. The design of mechanism is combined with the running speed of the crusher, so that the capacity of the crusher is larger and the wear of the jaw plate is low. The ideal crushing meshing angle ensures the crushing and smooth pass of materials, and the reduction ratio is larger.

◆Reliable heavy-duty moving jaw assembly

The moving jaw is made of high-quality cast steel and driven by large cast pulley and flywheel. Forged heavy eccentric shaft and SKF or FAG high-quality large self-aligning roller bearing make crusher more reliable. The moving jaw head is equipped with a replaceable plate, which can effectively protect the moving jaw from the impact of feeding.

◆Robust body structure

The body frame is composed of front cast steel fixed jaw, rolled steel plates on both sides and rear cast steel adjusting seat. Butt welding is adopted to improve the stress of the steel plate. The frame is annealed after assembly and welding. The frame has high strength, durability and simple structure.

◆Installation without foundation bolt

With good balance, the crusher does not need foundation bolts, and can work normally through rubber damping pads installed at the bottom and side of the crusher support.

◆Integrated motor installation

The motor support is installed with the crusher as a whole, which reduces the space and the length of triangle belt, makes the base simple, and can be equipped with standard pulley cover and flywheel cover.

◆Easy maintenance

With automatic bearing lubrication and hydraulic outlet adjustment system, it is easy to operate and maintain, which can fully meet the crushing requirements of large crushing production line.

Patents obtained:

1、Integrated motor installation of jaw crusher (Patent No.: ZL201120249189. X)

2、A wedge-shaped block adjusting structure of jaw crusher (Patent No.: ZL201821433137.6)

3、A jaw crusher with protective cover for easy disassembly and adjustment (Patent No.: ZL201821434272.2)

4、A plate for jaw crusher (Patent No.: ZL201822166872.1)

5、A jaw crusher with damping pad replacement mechanism (Patent No.: ZL201921209229.0)

6、A jaw crusher with fully enclosed cover (Patent No.: zl201922224201.0)

Applications:

A project in Pakistan

An iron ore project in Wugang City, Henan Province

A limestone project in Jiangsu

An iron ore project in Shaanxi

An iron ore project in Hebei

JC1200 jaw crusher applied in projects in Panzhihua

In addition, in order to adapt to the development trend of large-scale, NMS has specially developed a large jaw crusher JC2000M, with the power of 315kW and the processing capacity of 1200-1300t/h. It has been applied in the projects in Argentina and many places in China.